Fixing a Laser Cutter

Laser cutting is hands down my favorite way of prototyping things. It takes minutes to make new iterations of a design compared to the hours a 3D printer might need. Recently the laser cutter at the makerspace broke down and I was asked to have a look at it. Here's how I went about debugging and fixing it.

What's the problem?

I consider technical communication extremely important. I always like to show a video that clearly demonstrates what the problem I'm solving is.

In this case, it's quite simple. The laser cutter did nothing.

Why doesn't it work?

The first thing to check was the control box.

The control box is the nervous system of the laser cutter, it takes in instructions (G-code) from the computer and converts it into electrical currents that move the motors and turns the laser on and off.

It turns out, the control box had power coming in to it but no power coming out of it.

This means that the problem very likely lies with the control box. It would be pretty simple to just swap out the control box for a new one. However for environmental reasons and because debugging broken machines is often interesting I decided to give it a shot and try to fix it.

What's a control box anyway?

Before proceeding I'm going to provide a quick rundown of what's going on in the control box:

The X/Y/Z/U outputs control the X/Y/Z/U axis motors. The X/Y motors control the position of the laser head. The Z motor controls the height of the platform. The U axis is a rotation axis and on this particular machine connects to nothing.

At the limits of motion of the laser cutter, there are switches. If the laser head ever hits these switches, it stops moving. This is a safety feature and ensures the machine doesn't destroy itself. It's also essential for calibration so that the laser cutter can figure out where the laser head is whenever it needs to.

The display port just connects to an interface that provides cutting parameter information and allows the user to control the laser cutter (i.e. start cutting, move the laser head, etc).

Why won't the control box control stuff?

As it turns out, the control box was designed to receive 24 volts but had 36V going in instead. I suspected this high voltage had fried something inside. I opened up the circuit to have a look at what's going on.

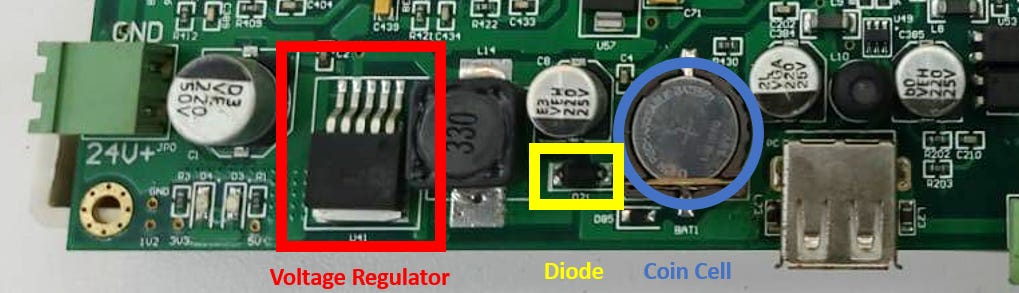

There were a whole bunch of communication and control chips but because everything on the board stopped working, I had a hunch that the board's power circuit was blown and decided to poke around there. I connected the control board to a power supply and started testing components one at a time. These were the issues I found:

The voltage regulator is supposed to take in 24V and convert it to 5V for other chips on the circuit to use as a power source. This voltage regulator had internally shorted and just sent out 24V instead of 5V.

This diode seems like it's is supposed to prevent power flowing into the coil cell when the circuit is connected to a power supply. In this case it had internally shorted and just caused the whole circuit to short out.

Coin cell was out of charge. It was at 0.4V instead of 3V.

While I don't think the coin cell plays a particularly important role in this control circuit it was cheap enough to replace anyway. The other two, though were either the cause of or related to why the laser cutter wouldn't work.

At this point I also looked at the datasheet of the voltage regulator to see if the 36V power supply was what damaged it. As it turns out, this voltage regulator could handle voltages of up to 40V, so feeding it 36V wasn't a problem.

I'm still not quite sure what caused these components to fail but for now I'm going to chalk it up to them just being old. If this fails again I can try and figure out what's causing the failure.

Repair

I ordered the 3 damaged components off Taobao and replaced them. I was a bit worried that once I fixed this, other issues would crop up. However the control board now worked on my desk, so it was time to plug it back into the laser cutter.

I decided to connect the motors back one at a time so that if something broke, the damage would be limited to just a few components.

Turns out everything worked fine and the laser cutter was back in action!